Custom Glass

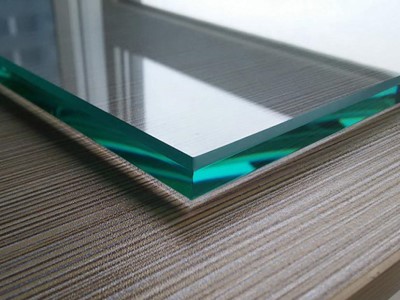

Ordering Toughened Glass Online

Toughened glass is also known as tempered safety glass. It is produced by first cutting and processing sheets of glass, which are then loaded into a furnace, making the glass 4-5 times stronger than regular float glass. All our glass products are toughened to British Standards (BS EN 121500:2000) for safety as well as making the glass 4-5 times stronger. All orders go through a rigorous quality assurance process in order to guarantee satisfaction. If we cannot fulfil your glass measurements online, do not hesitate to contact us with your requirements. Here at PradGlass we take pride in making every solution unique.

Delivery & Lead Times

Please allow up to 15 working days for manufacture and delivery. Oversized and CNC Panels can take from 20-25 working days. All delivery times are estimates and therefore cannot guarantee that any delivery will reach you on a certain date or at a certain time as we outsource all deliveries to third parties. We therefore recommend that you do not organise workmen until your goods have been delivered so that you can avoid any such loss.

Toughened Glass Products

Speciality Edge Finishes

This is our standard finish. The edge is ground at 90 degrees to the top surface of the glass and is finished with gloss finish. A 45 degree chamfer on the top/bottom removes the sharpness from the glass.

This type of edgework adds a sense of depth on the glass. Typically used for mirrors, the edge is ground off, giving it a decorative look. Most bevels are ½” or 1″. These are the most common, however, several other widths are available.

This type of edgework results in an edge that is slightly rounded. Pencil Grind edgework has a frosty, matte, or satin finish. Pencil Polish edgework provides a glossy, shiny finish.

Please feel free to contact us at any time to discuss your requirements in more detail.

| Glass Processing | |

| Maximum Panel Size | Our online calculators can process sizes up to 900mm x 2800mm. This is the maximum size we can ship out via our couriers. For all sizes greater than this please get in touch as special glass couriers will be required to deliver this glass. |

| Minimum Panel Width | Some restrictions apply to cutting glass as it is very difficult to cut a strip of glass less than the glass thickness. panels thinner than 60mm in any given dimensions will be processed with 3 sides polished and non-toughened glass. |

| Flat Polish (P.A.R) | All our glass comes with flat polished edges as standard. This is produced by a straight line edging machine and produces a fine polished flat edge suitable for situations where the glass has exposed edges as used in furniture glass and all frameless toughened glass applications. |

| Bevelled Edges | With straight line and shaped bevelling a beautiful and decorative touch can be added to mirrors, table tops, glass door panels and furniture glass. Available on glass thicknesses 4 - 19mm in a variety of bevel widths and on annealed or toughened glass. The bevel width available is dependent upon glass thickness and the required residual edge. |

| Tolerances | We manufacture our glass products using different processes, determined by the requirement of the glass product to be made. Because of this, tolerance ranges do vary by the design of the item. We follow all best practices and guidelines outlined by the Glass and Glazing Federation (GGF) and work with the advised nominal tolerance of ± 2mm on all toughened glass products. Laminate glass and decorative glass tolerances may vary. |

| Dubbed Corners | The sharp corner of the glass it lightly sanded off manually to remove the sharp point. Not as neat as radius corners, dubbed corners are still heavily used just to take off the sharp point and add safety. |

| Drilling (Holes) | |

| Hole Diameter (Ø) | The hole diameter must be greater than or equal to the thickness of the glass with a minimum of 6mm. |

| Distance from the Edge | The distance from the edge of the hole to edge of the glass must be greater than or equal to 2 times the glass thickness. For glass 4 to 6mm thick, this hole distance can be reduced to 1.5 times the glass thickness. |

| Distance from a Corner | In a corner the hole must be greater than or equal to 4 times the glass thickness from the corner and greater than or equal to 2 times the glass thickness from the other edges. |

| Distance between Holes | The distance between holes must be greater than or equal to 4 times the glass thickness. |

| Large Hole Diamters (Ø) | Large hole diameters must be less than or equal to 1/3 of the pane width and height. |

| Minimum Panel Size | In any pane with holes, the minimum width or height of the pane must be 8 times the glass thickness. |

| Internal Cut-Outs and Notches | |

| Distance between a Cut-Out and Glass Edge | The distance of the cut-out to the glass edge must not be less than 30mm for glass up to 6mm, and 50mm for glass over 6mm. |

| Distance between a Notch and Glass Edge | The distance between a notch and the glass edge must be greater than or equal to 75mm. |

| Internal Radius of Cut-Outs and Notches | All rectangular cut-outs must have radius corners with a minimum radius either greater than or equal to the glass thickness. All notches must have holes or radius corners greater than or equal to the glass thickness. |

| Cut-Out Height or Width | The height or width of a cut-out must not be less than or equal to 1/3 of the pane height or width. |

| Semi-Circular Cut-Outs | All cut-outs with semi-circular ends must have a 20mm minimum radius and internal corners with a minimum radius greater than or equal to the glass thickness. |

| 'C' Notches | Half hole ‘C’ notches must have a radius greater than or equal to the glass thickness and a slot opening greater than or equal to the glass thickness. |